Joyo has plenty of experience in working customized furniture parts for customers from different countries.

Most of the furniture parts are worked from aluminum, stainless steel, and steel, the process include aluminum extrusion, CNC machining (turning and milling), die castings, as well as welding.

And the surface treatment are usually in sand blasted, polishing, brush, powder coated, anodized and so on.

To work furniture parts, it needs to be pretty careful to the surface, protect the surface and without any burrs, defects and so on.

Our customers use these parts for outdoors, shopping malls, homes and so on.

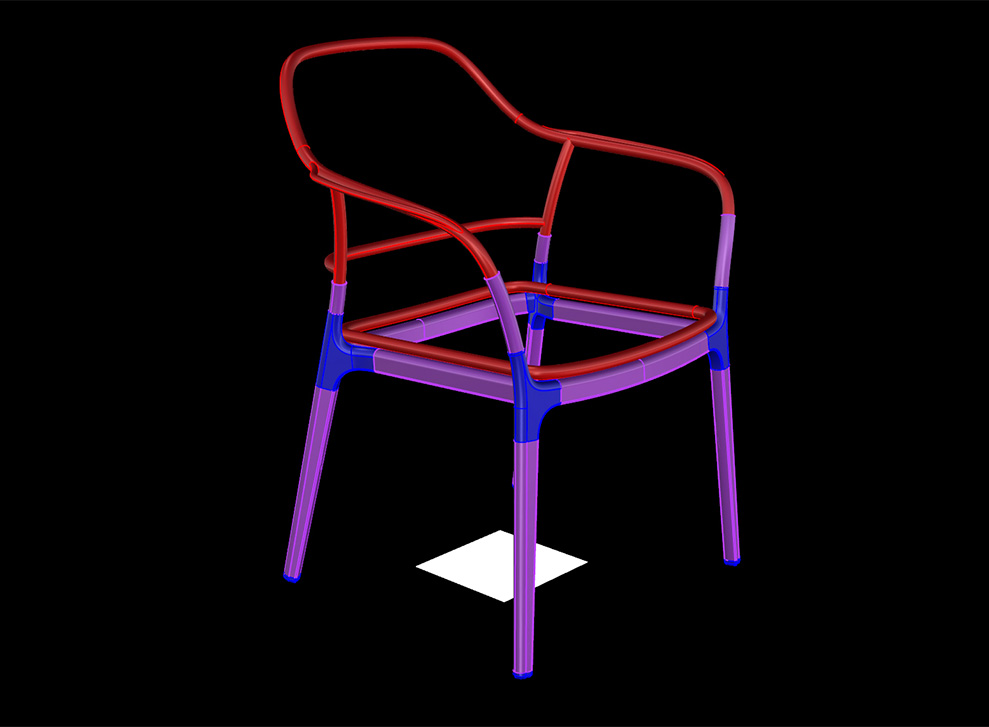

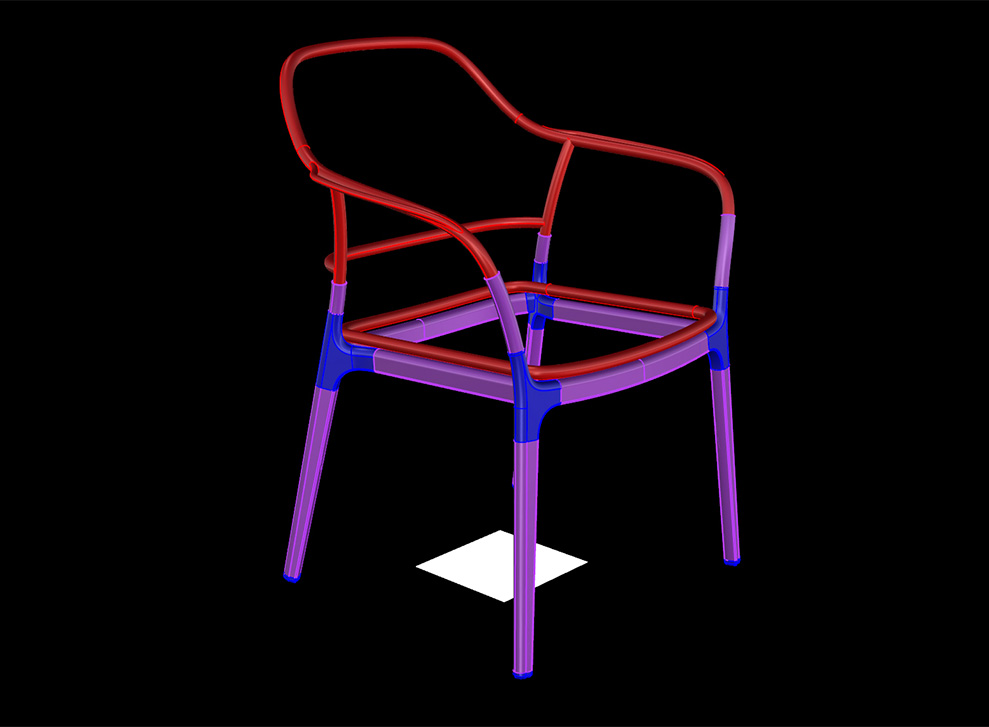

Here is one example for our project .

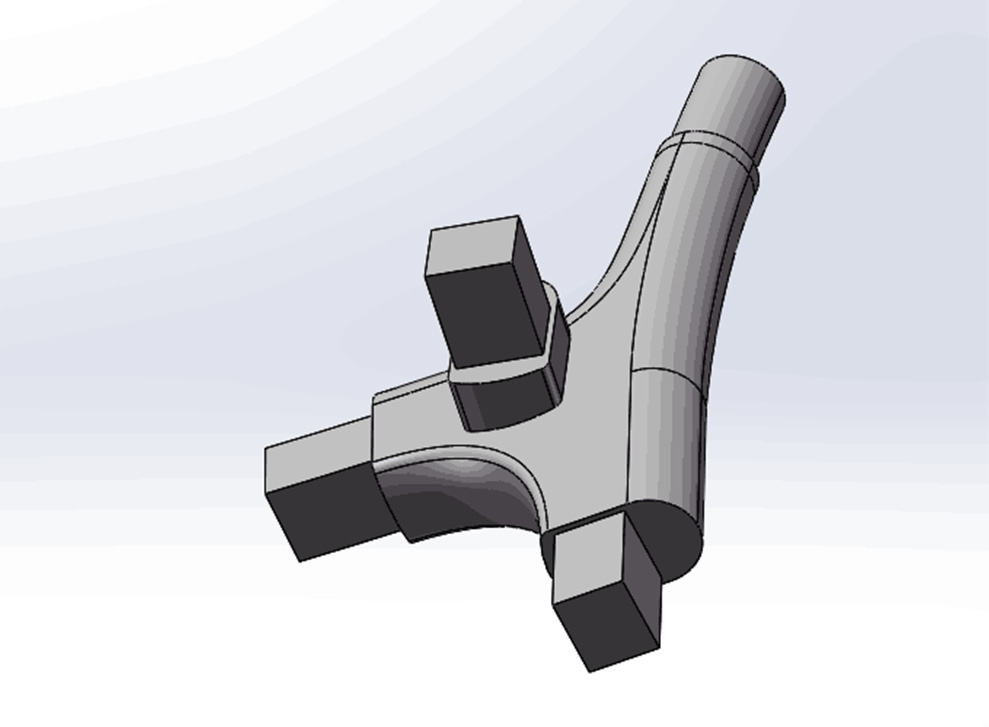

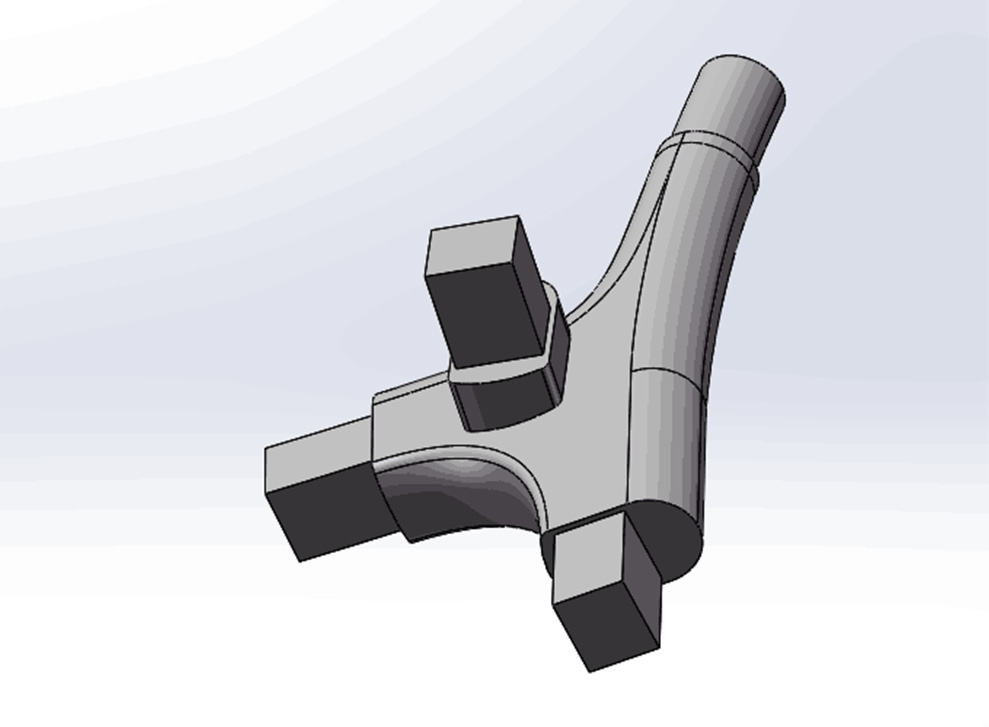

| 1、Design from our customer with CAD drawing and 3D print. | 2、DFM Analysis of die casting connector, and change the drawings, remove sharp edge , make small draft angle meet die casting process. |

We analysis there are 2 pairs of aluminum connectors made by die casting , and others worked by aluminum tube forming. |  |

3、After all confirmed by customers, we proceed with the die casting mold in around one month. Two mold needed, left and right, 1-1 cavity with life 80000 shots.

4、First article sampling comes after mold finished,

5、Cut the sample into pieces and check if air hole or porosity issue exist.

|

mass-production after sample approved by customer. |

6、Welding the die casting connector with aluminum extrusion tube and grinded.

Small air hole may happen in this process because there are two different aluminum alloy, one is ADC12, another one is 6063. Then welding repair or poly-putty to repair.

7、All welded and grinded in nice surface.

8、Overview of aluminum chair , before powder coated.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски