Product Introduction

The Canto Nxt is a versatile tilt-in-space wheelchair designed for comfort, adjustability, and safety. Its modular frame accepts various add-ons, including different wheels, seats, backrests, leg rests, and drives, allowing for personalized configurations. Our part is the bracket for the Canto Nxt.

Material and process

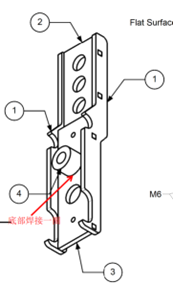

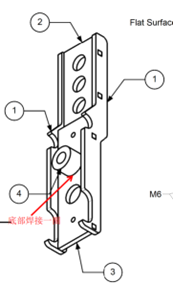

Here is the sketch.

There are 4 different parts assemble together, No.1 side plate has left and right piece, but the same.

5mm thick mild steel used in this canto bracket, laser cutting is suitable to cutting pieces.

Laser cutting is widely used in industries such as automotive (sheet metal parts), electronics (circuit board components), aerospace (lightweight metal structures), and textiles (fabric cutting with high precision).

Laser cutting harnesses the concentrated energy of a laser beam to thermally or chemically alter materials, combined with precise motion control, to achieve accurate and efficient material shaping.

After laser cutting, the plate are fixed in a special jag tooling and going to TIG welding. TIG welding (Tungsten Inert Gas welding), also known as gas tungsten arc welding (GTAW), is a precise arc welding process that uses a non-consumable tungsten electrode to generate an arc for melting the base metal and filler material.

It also include one bushing which was CNC turned and welding around with welding seam 5mm.

After all welding, canto nxt brackets are sent to shot blasted, to make the surface uniform and deburrs.

Its surface is Black zinc plated, is a process of depositing a protective zinc coating onto a metal substrate using an electrolytic cell. This technique enhances corrosion resistance and provides a durable surface finish for various materials, primarily steel. It is usually colorful zinc such as blue and red, black zinc plating is rare and expensive due to requiring precise control of heavy metal salt solutions and precious metal salts and longer plating time increase production expenses.

Packing

The brackets were packed in bubble bag individually when the production finished to protect the surface from bumping and scratch. Then packed them in carton and laid on the pallet, and wrapped with protective film, ensuring the cartons don't fall apart.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски