Product Introduction

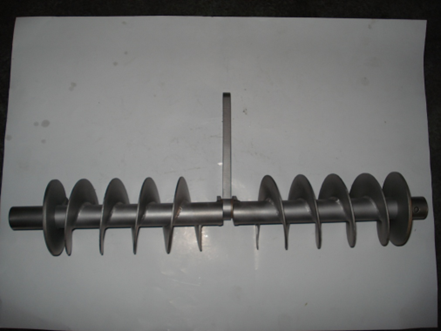

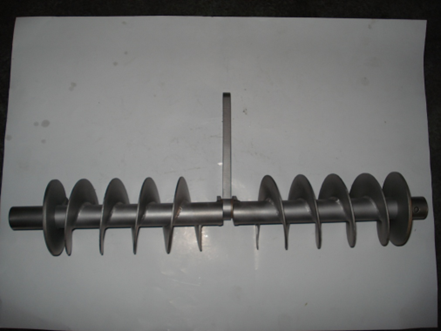

This is a special 304 stainless steel auger for feed equipment, including the flight, stainless tube, handle, and bronze bushing.

The stainless steel flight is formed with a mold, and the tube is made from standard 304 stainless steel seamless tube.

The handle is laser cutting and grinded. Bronze bushing is made by powder metallurgy process with mold.

All these are welded together.

This auger component is custom-designed by an engineer in the feed equipment field. It easily transports feedstuff from both sides to the center, so the material flows in one direction.

1.Design feature

After the customer provided the 3D drawing, we used SolidWorks to divided it into separate parts. We discussed details with engineers and confirmed the final drawing together.

2.Material and proess

The center tube is seamless tube of stainless steel grade 304. Each full length is 6 meters, and we cut it into pieces as needed. Check out the pics below to see how it looks.

The 304 stainless steel flights, which are extruded or pressed by a custom die from stainless steel strip into auger shape. And the custom stainless steel flight in opposite direction. Take a look at the images to see the different designs.

The center bar also is made of stainless steel 304, as the thickness reach 12mm and need nice surface, we choose wire-cutting instead laser cutting process and grind the cutting face.

And the cam bracket , total 2pcs, worked the same as center bar.

Oil Filled Sintered bronze bushing, which is made from powder metallurgy process. See the following picture.

As all parts are ready, center bar, bushing, bracket are fixed and welded into center tube by jaw tooling, to make sure it is in center location. Then left and right stainless steel augers are full welded into tube.

After that, cut off the center location of the tube, make sure the center bar can rotate. See the picture.

In this way, the flight can keep it straight.

To make the whole component in good looking, the auger component was sent to glass beads blasted, see picture.

3. Packing and shipping :

Special size of carton made to pack augers, two pieces are packed in one carton.

Then laid into wooden case and sent to Canada.

Clients trust us because our assembled parts stand the test of time

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски