Product Introduction

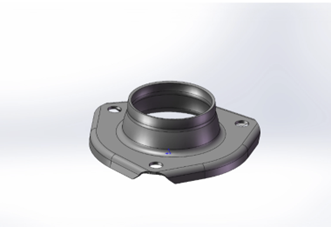

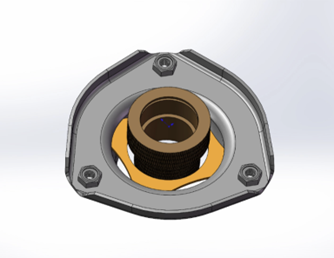

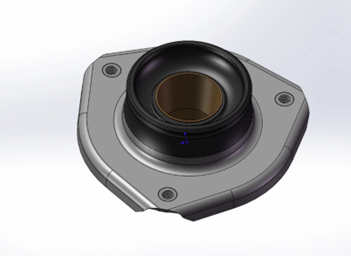

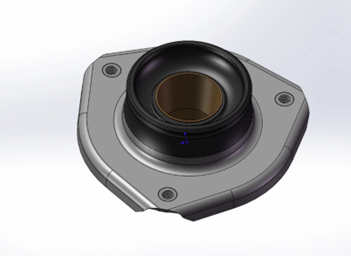

This shock absorber top rubber mouting is used in automotive shock absorber. Rubber is always a great choice for soaking up vibrations. Our rubber assemblies are fully custom-made based on our customers' designs.

Material and proccess

Material introduction

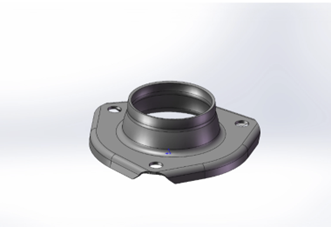

The top frame or housing is made from AISI 1020 mild steel. Getting the dimensions right is a key, especially those the 2 holes with nuts—they're crucial for fitting everything together. The frame is formed using a deep drawing process with multiple molds. It's similar to punching, but not exactly the same.

Product display

And we can make deep drawn steel frames in many kinds of sizes, check out the picture below.

Drawings analysis

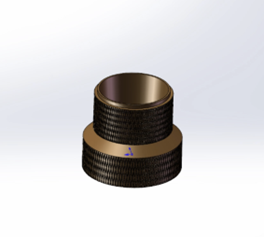

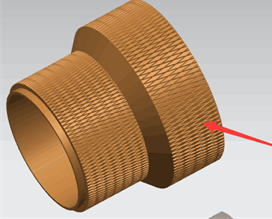

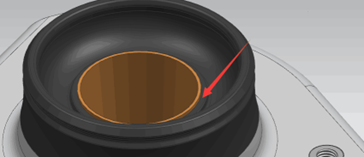

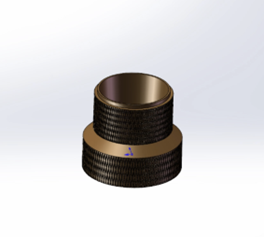

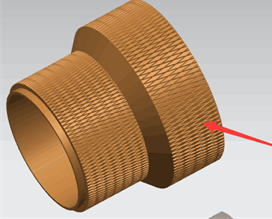

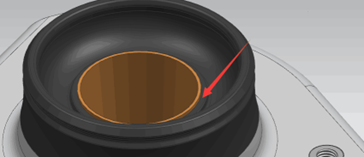

The inner steel bushing is made from AISI 1045 carbon steel. By CNC turning it from a solid rod. The center hole has a tight tolerance of +0.03 and a surface roughness of Ra1.6. Why such strict specs? Because it fits into a ball bearing, so precision matters. The outer surface is fully knurled to RAA1.0—that texture helps it bond with the rubber when we inject mold it. Check out the pic below to see the details.

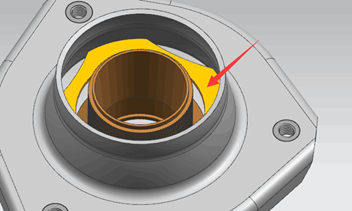

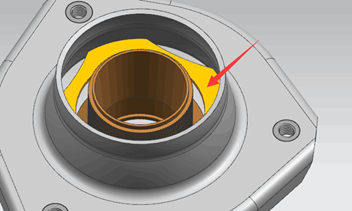

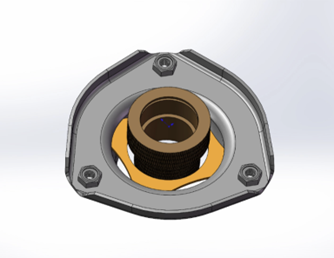

The inner steel bracket is pretty simple in shape, just 3mm thick. We stamp it out using a punch mold. After that, we weld it to the frame, see what that looks like in the picture.

Three welding nut also welded in the hole of frame, and fix the frame, bushing in a correct location by tooling.

After all ready, the fixture was injected by nature rubber, hardness shore 55-65.

Surface finish

Black painting is necessary to protect the rubber assembly to avoid rusty, as well as nice surface, ball bearing with snap ring will be assemble at last.

Packing

Each product is wrapped in a bubble bag and then packed into cartons. The cartons go onto pallet with shipping marks. The goods is usually shipped by sea since it's the best option. Customer is satisfactory for all the effort we do.

Ningbo Joyo Metal Products Co.,Ltd. don't just manufacture parts, we also specialize in product assembly. From component machining to final testing, our team ensures every assembled product meets strict quality standards.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски