Production Introduction

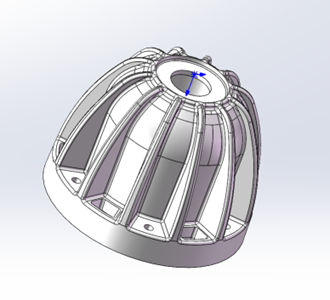

Aluminum LED downlight housing is a crucial component for LED downlights. Crafted from aluminum, it offers excellent heat dissipation properties, effectively transferring the heat generated by the LED chips to the surrounding environment, which significantly extends the lifespan and enhances the performance of the LED light. Its lightweight yet durable structure provides good mechanical strength, protecting the internal electrical components from physical damage.

There are dozens model of aluminum led down light housing, all are design from customer's drawing.

Material & Process:

The down light housings worked by die casting process , and used most popular die casting aluminum alloy ADC12.

It is a die-casting aluminum alloy specified by the Japanese Industrial Standard. It is equivalent to YZAlSi11Cu2 (or YL113) in China's GB standard, A383 in ASTM (US), and EN AC-44100 in European standards. Belonging to the silicon-copper aluminum alloy series, it is renowned for its excellent die-casting performance and balanced mechanical properties, widely used in automotive, electronics, and machinery industries for cast components. ADC12 aluminum alloy stands as a cornerstone in die-casting due to its optimal balance of castability, cost, and performance.

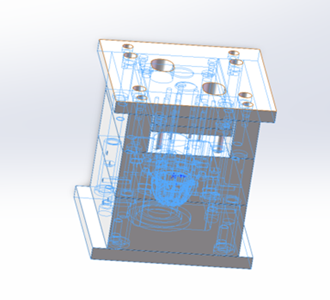

When customer send us the drawing of down light housing, we analysis the drawing and confirm with customer, and then we make the 3D printing of die casting injection mold.

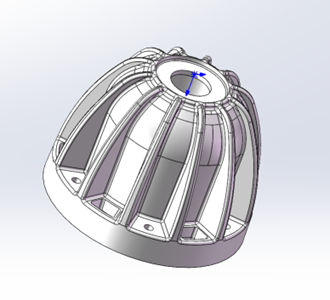

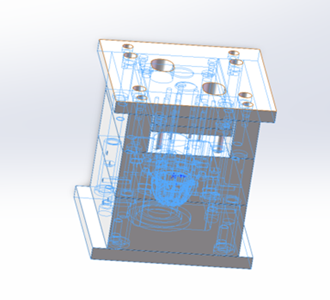

3D drawings of down light housing

3D printing of die casting injection mold

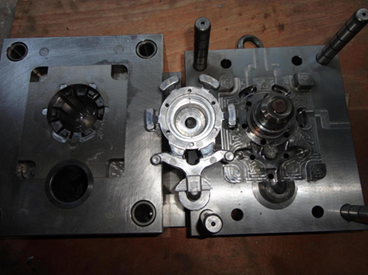

According our design, the part are die casted in 1-1 cavity and mold include upper mold and bottom molds, mold frame and mold core. After mold drawing confirmed , we move to next step to make mold.

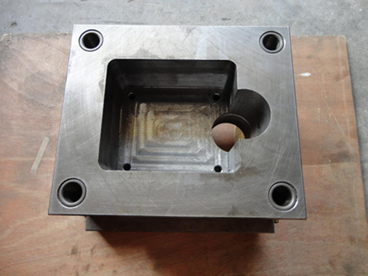

3/4-axis machining centers is used to process the mold, cutting speed 100~300m/min, feed rate 0.2~0.5mm/r.

Removes bulk material using end mills and face mills, leaving 2~5mm machining allowance depending on precision requirements. Then wire EDM cuts complex shapes and 5-Axis machine handles complex curved surfaces. Finally the mold was sent to heat treatment and surface finish.

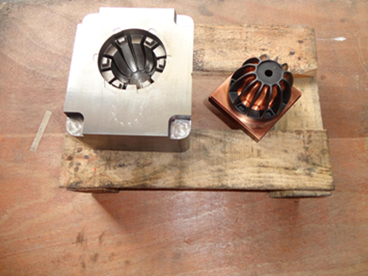

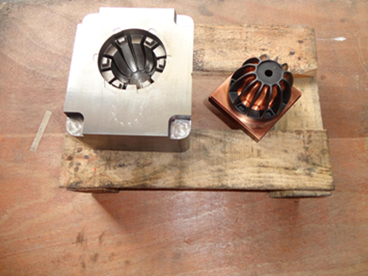

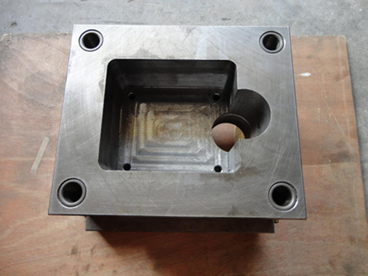

After around 4weeks hard working, we would see the mold, shoot sleeve and so on.

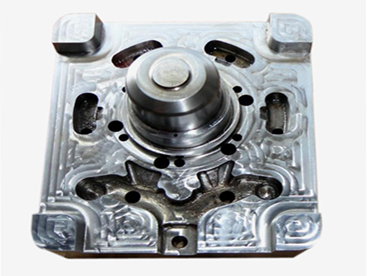

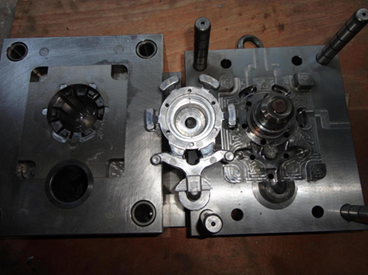

the mold part-1

the mold part-2

the mold part-3

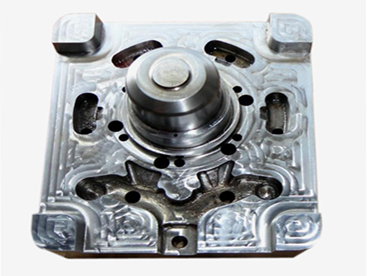

the mold of led down light housing

When the mold is ready, our staff equip the die casting mold into 280ton machine to die cast the down light housing.

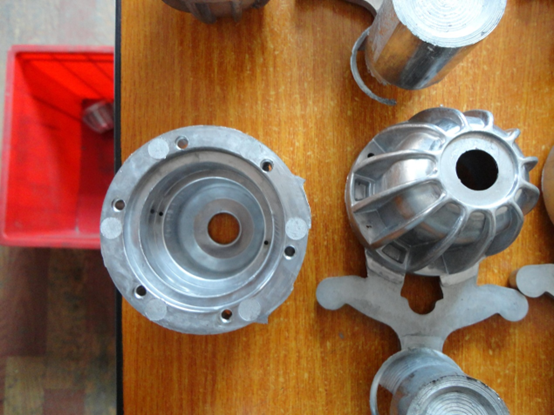

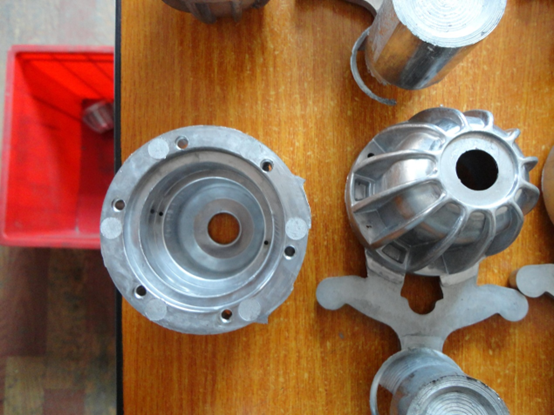

Here is the sample:

The mass production began to be produced after the sample getting approval, the product undergoes deburring, grinding, and finally, sandblasting treatment when they were die casted.

Packing:

To protect the product surface, each item is individually wrapped in a bubble bag and then packed in a wooden case to cushion impacts. This dual-layer packaging ensures that the surface remains free from scratches or dents during transportation, with the bubble wrap providing a shock-absorbing buffer and the wooden case offering robust structural protection.

Ningbo Joyo Metal Products Co.,Ltd. specialize in various metal process, serving industries ranging from automotive parts, furniture, and lighting to wheelchairs. Our expertise covers precision machining, casting, forging, and surface treatment, enabling us to deliver customized solutions for diverse applications.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски