Production Introduction

This is a very unique portable square steel LED flash light housing, our customer involve with flash light industry and we supply the housing to them. This is a high-power and highly practical flashlight, primarily designed for outdoor use. It can remain lit for extended periods and offers a wide illumination range, making it an essential tool for outdoor work. What sets it apart from other products is its larger battery capacity, ensuring longer-lasting performance during adventures or professional tasks.

Material and process:

Aluminum alloy is our choice to work this flash light housing, for it is light and good for heat dissipating.

First we made 3D printing for the housing, and then unfold the drawing to 2D.

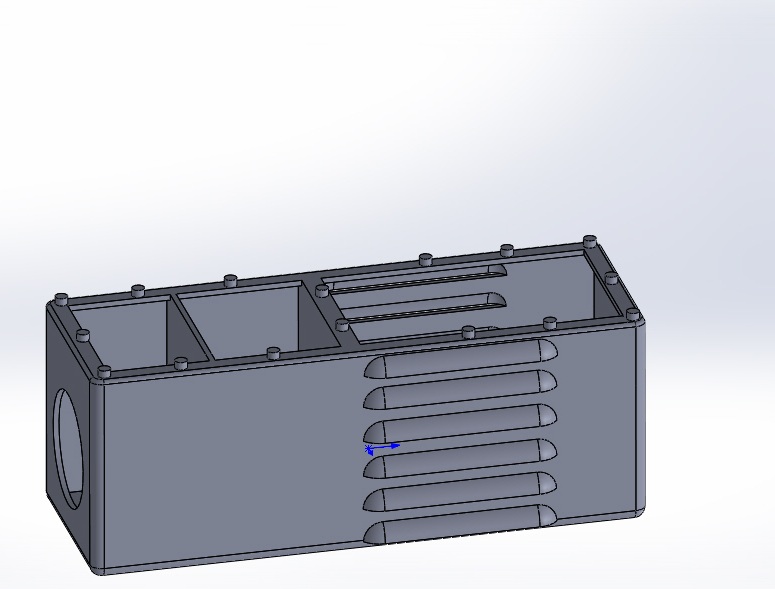

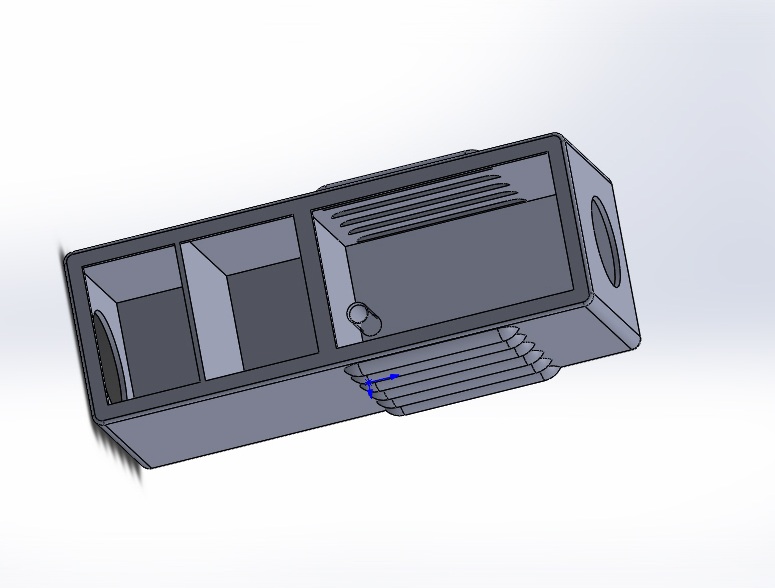

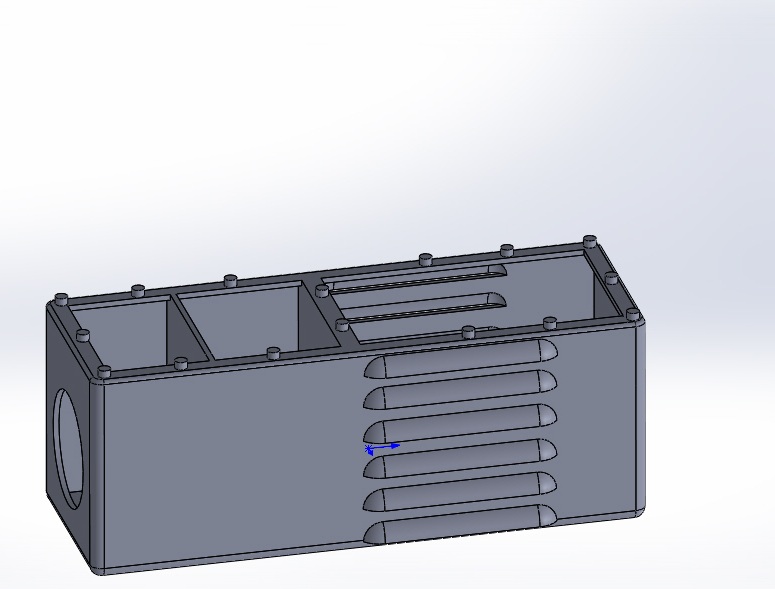

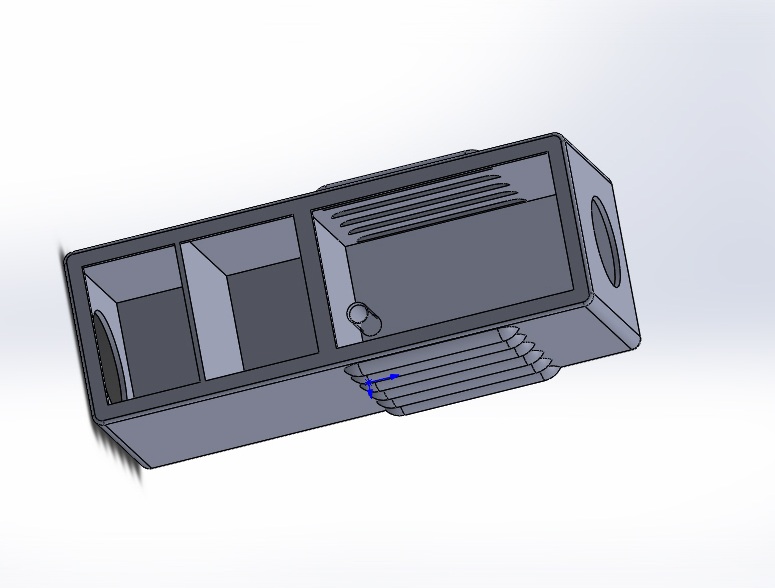

Here are the 3D drawings of this flash light housing.

Flashlight 3D drawings-1

Flashlight 3D drawings-2

We choose 5052 aluminum alloy sheet, 2mm thick to work it. 5052 aluminum sheet is a material valued for its corrosion resistance, formability, and lightweight strength. Its performance in harsh environments and ease of fabrication make it a staple in application. It is thin and easy to laser cutting and forming according the drawings.

laser cutting

bending

Special we made air vent in two sides to help cooling, there are many types of vent which we are professional with that.

Then welded all sides together and also weld walls to divide the housing into three space.

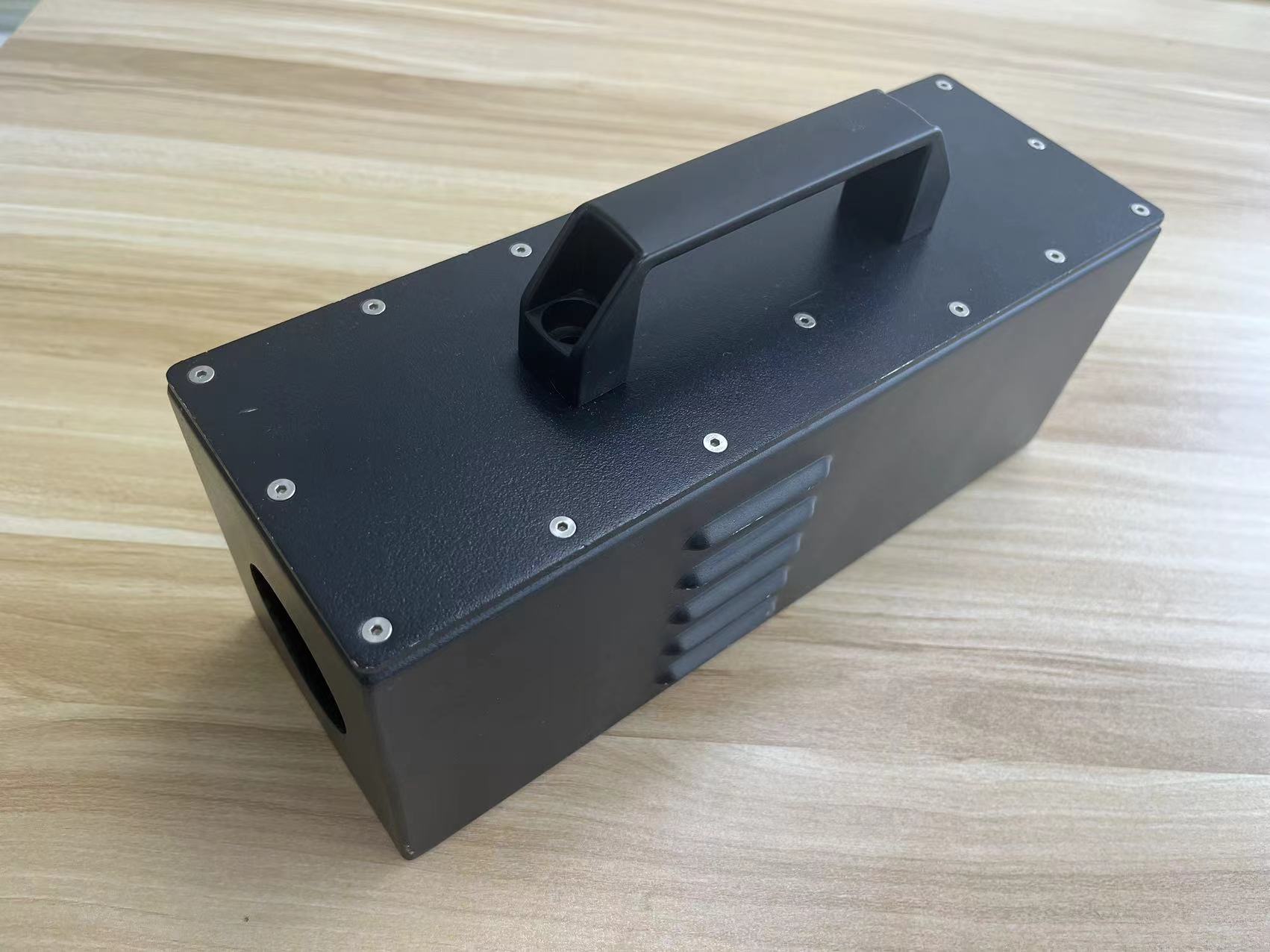

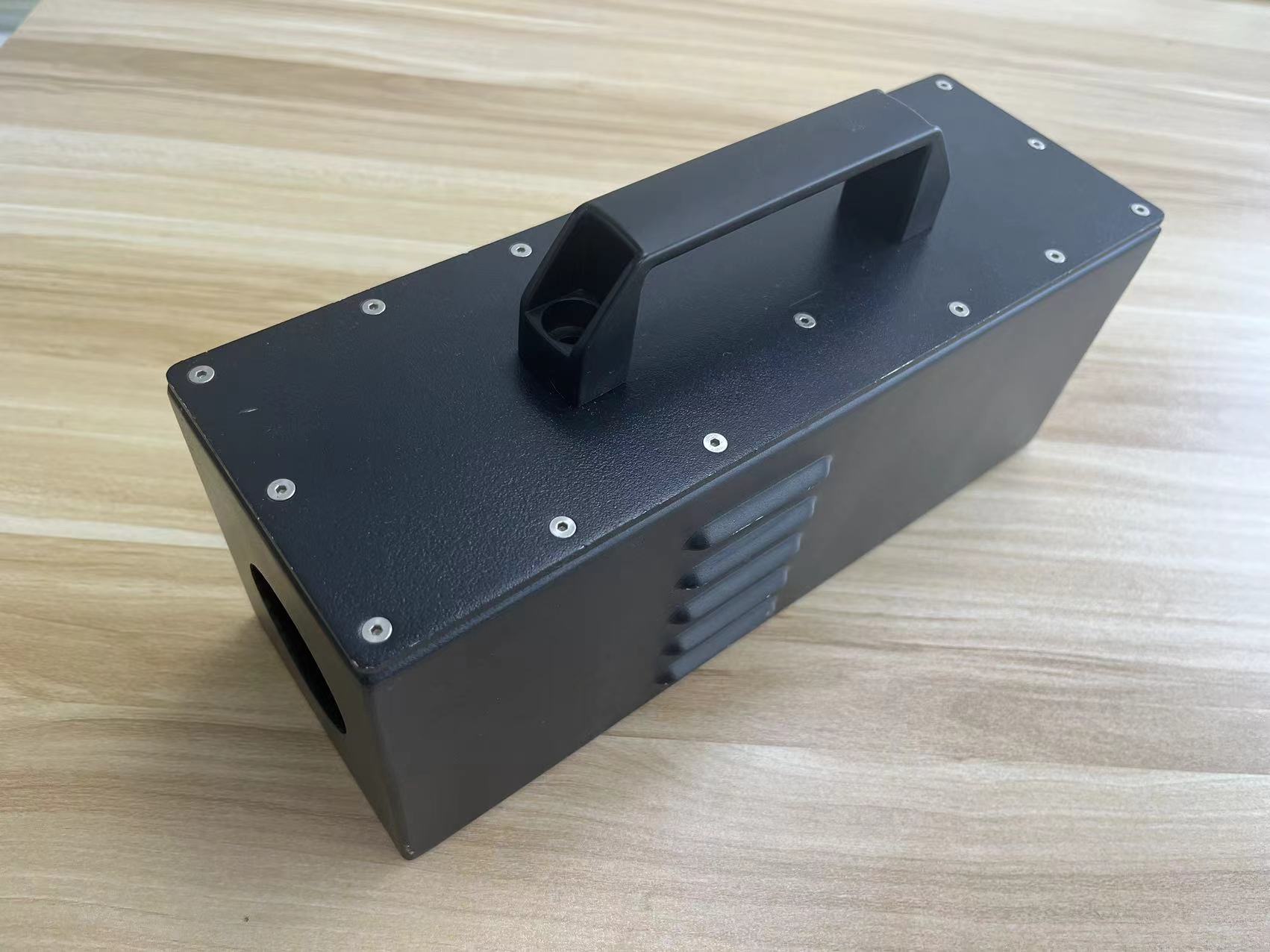

After bending and welding, we grind the welded joints to eliminate any visible welding marks and all parts are sent to sand blasted and black powder coated.

LED lamp housing- top plate

LED lamp housing- body-top view

Finally assemble the housing parts, there is one aluminum handle on the top so that it is easier to take it. Aluminum handle is worked from die casting process. As the below picture:

Packing:

For such outer products we take extra care when packaging products and use boxes to package them individually to avoid scratching the surface, then put into cartons and laid on pallet, wrapped the pallet and cartons to ensuring fixing the goods free from bump and scattering.

Ningbo Joyo Matal Products Co.,Ltd. don't just craft products with dedication, we pour effort into every step of the process, striving to ease customer concerns and address their pain points to the fullest.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски