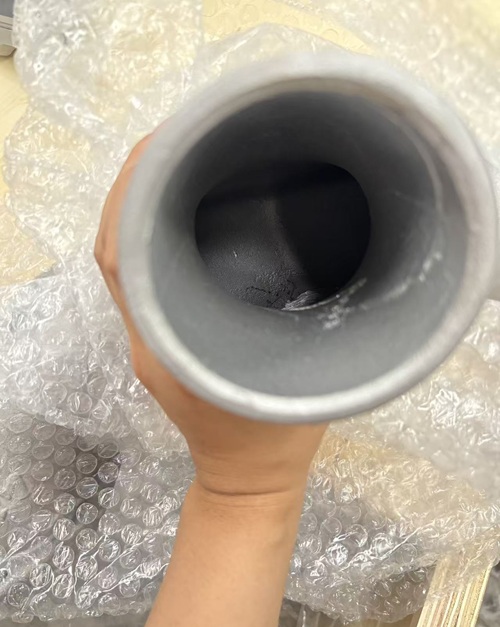

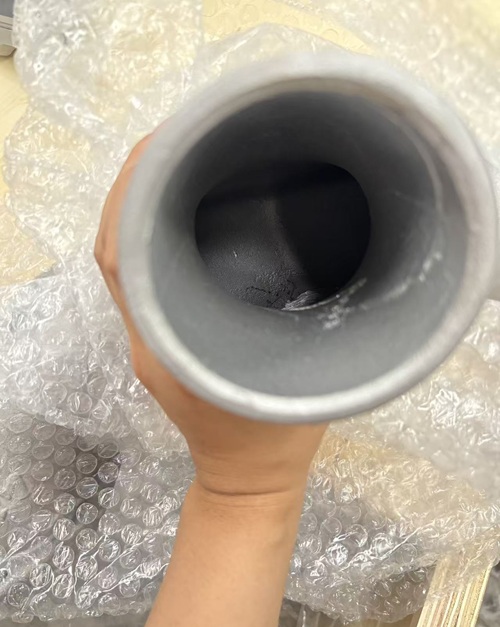

Precision Casting has long been valued for its ability to produce complex shapes with high dimensional accuracy. Yet when components are hollow, the challenge of ensuring clean and smooth inner walls becomes more pronounced. Rough or contaminated surfaces inside castings can reduce fluid flow, impair sealing, accelerate fatigue, or even cause hygiene issues in industries like food or aerospace. At Ningbo Joyo Metal Products Co., Ltd., we understand how critical these factors are, and through a combination of advanced process control and post-casting finishing technologies, we help our customers achieve consistently reliable results.

Why inner-wall finish matters in hollow castings

The quality of internal surfaces directly determines the performance of many products made by precision casting. When inner walls are rough or uneven, fluids and gases may not flow as intended, leading to turbulence, pressure loss, or localized hotspots in exhaust systems. In sealing applications such as valves or hydraulic housings, poor finishes increase the risk of leakage. Fatigue life is also shortened when surface irregularities act as stress concentrators.

Cleanability is another key concern. In industries such as food processing or aerospace, internal cleanliness standards are strict, and residue from casting must not remain inside the component. Smooth inner walls improve cleanability, lower the risk of contamination, and extend the service life of the part. Manufacturers therefore place significant importance on controlling these surfaces right from the design and casting stages.

Common causes of rough inner walls in precision castings

Several factors can lead to unwanted surface conditions inside hollow castings:

Core material and binder residue

Cores used to create cavities can leave behind sand particles, binder films, or ash residue if they do not fully collapse or burn out during the process. This results in abrasive inclusions and rough spots on the inner surface.

Inadequate venting

When gases generated during metal pouring cannot escape effectively, they form bubbles or porosity in the inner wall. Such gas entrapment often creates an uneven finish and weak points in the casting.

Mold or coating defects

Deficiencies in mold coatings or refractory washes may cause flaking or chemical reactions with molten metal. This leads to surface scabs, inclusions, and other irregularities inside the cavity.

Pouring parameters and turbulence

If molten metal is poured too quickly or at inconsistent temperatures, turbulence may erode the core or trap oxides against the wall. These defects appear as rough, uneven textures that can compromise performance.

By understanding these causes, engineers can begin to design casting systems that minimize surface problems before they occur.

Prevention at the casting stage: core, mold and process controls

Achieving smooth inner walls in precision casting is most effective when problems are prevented during the design and pouring stages. Several methods are widely applied:

Core material choices and refractory coatings

Selecting the right core material is essential. High-quality silica, alumina, or zircon sands reduce the risk of residue. Applying uniform refractory coatings to cores ensures a barrier between the core and molten metal, preventing reaction layers and facilitating easier removal.

Venting design

Well-designed venting paths allow gases to escape from cores during casting. Without these channels, trapped gases can disrupt the metal flow and damage the internal finish. Modern venting design often combines small vent holes with permeable coatings to ensure smooth filling of cavities.

Controlled pouring and mold temperature

Stable pouring conditions reduce turbulence and help metal flow evenly along core surfaces. Proper mold preheating ensures the molten metal wets the cavity consistently, reducing defects. Controlling mold temperature also minimizes thermal stress on cores, lowering the risk of flaking.

Vacuum or low-pressure casting

For critical applications, advanced methods such as vacuum casting or low-pressure die casting can be used. These processes control metal flow more precisely, reduce oxide formation, and improve the surface quality of internal cavities.

At Ningbo Joyo Metal Products Co., Ltd., such preventive measures are part of our everyday process controls, ensuring that customers receive castings with the highest internal quality.

Post-casting interior finishing techniques

Even with the best process controls, some castings require further surface refinement. Various finishing techniques help ensure smooth, clean inner walls:

Abrasive Flow Machining (AFM)

Also called extrude honing, AFM forces a semi-viscous abrasive media through the internal passages of the casting. As the media flows, it removes microscopic peaks, burrs, and residues, polishing the walls uniformly. AFM is particularly effective for complex shapes and intricate channels that cannot be reached by traditional tools. This method is widely applied in motorsport, aerospace, and fluid-handling parts where flow efficiency is vital.

Electropolishing

For stainless steels and corrosion-resistant alloys, electropolishing provides excellent results. The process dissolves surface asperities electrochemically, leaving a smooth, bright, and passivated inner surface. Components such as medical devices, food equipment, and aerospace fittings benefit greatly from this treatment.

Chemical mechanical polishing and chemical milling

In cases where AFM or electropolishing are not practical, hybrid techniques can be used. Chemical mechanical polishing combines abrasives with reactive chemicals, while chemical milling selectively dissolves thin surface layers. Both methods can improve smoothness inside narrow passages.

Thermal energy methods

Techniques like thermal energy deburring use controlled combustion inside passages to remove burrs and loose residues. While less common than AFM, they can be applied when burr elimination rather than polishing is the priority.

These finishing methods extend the performance of precision castings and ensure they meet strict customer requirements.

Inspection and acceptance of internal surfaces

Once finishing is complete, inspection is essential to confirm that inner walls meet specification. Several techniques are used:

Borescope and endoscope inspection

Flexible optical devices allow direct visual examination inside cavities. Engineers can detect surface irregularities, residues, or incomplete polishing in real time.

CT scanning and X-ray analysis

For complex geometries or hidden passages, non-destructive methods such as industrial CT and X-ray reveal internal defects. These methods provide cross-sectional images, allowing precise quality assurance.

Surface roughness metrics inside cavities

Specialized probes and replica methods can measure roughness values in internal passages. This quantifiable data ensures castings meet contractual or regulatory requirements before they are delivered.

By combining advanced inspection with strict acceptance criteria, Ningbo Joyo Metal Products Co., Ltd. ensures every hollow component matches the intended quality.

Conclusion

Smooth internal surfaces are not just a finishing detail—they are central to the performance, durability, and reliability of hollow components produced by precision casting. At Ningbo Joyo Metal Products Co., Ltd., we apply a staged approach that starts with core and mold design, continues with precise process control, and concludes with advanced finishing methods such as Abrasive Flow Machining and electropolishing. Through this approach, we provide customers worldwide with castings that meet the most demanding standards. For more details on our precision casting solutions or to discuss a project, please contact us today.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски