Product Introduction

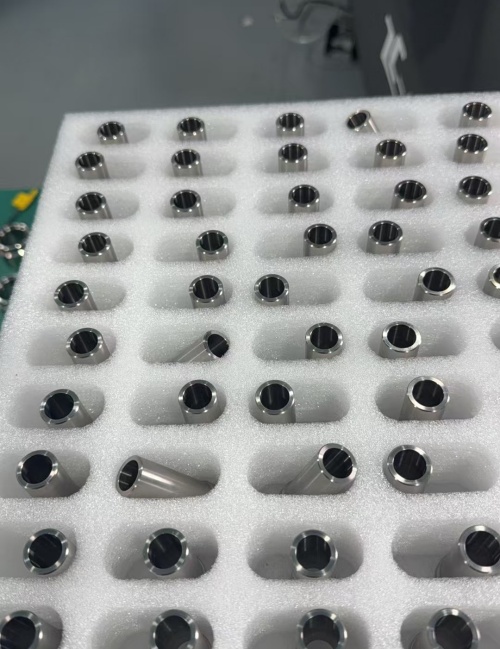

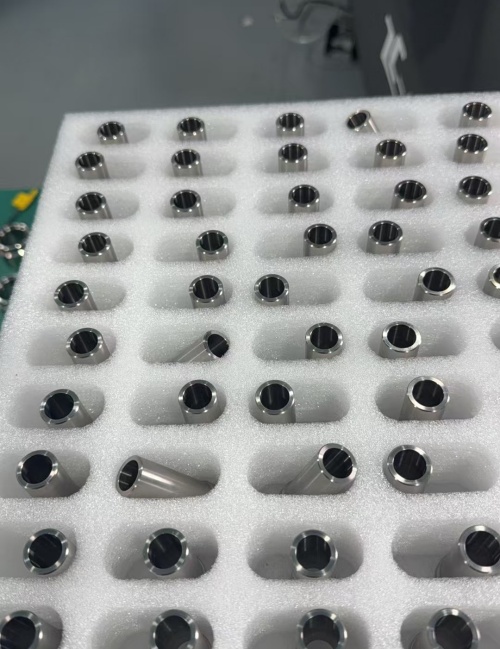

Every style of this bushing is designed to fit specific application needs. From dimensional parameters, such as inner diameter, outer diameter, length, and wall thickness to intricate features like oil grooves, threaded holes, or tapered surfaces, each detail is customized. These bushings are made from titanium alloy rod by CNC machining process.

Material and process

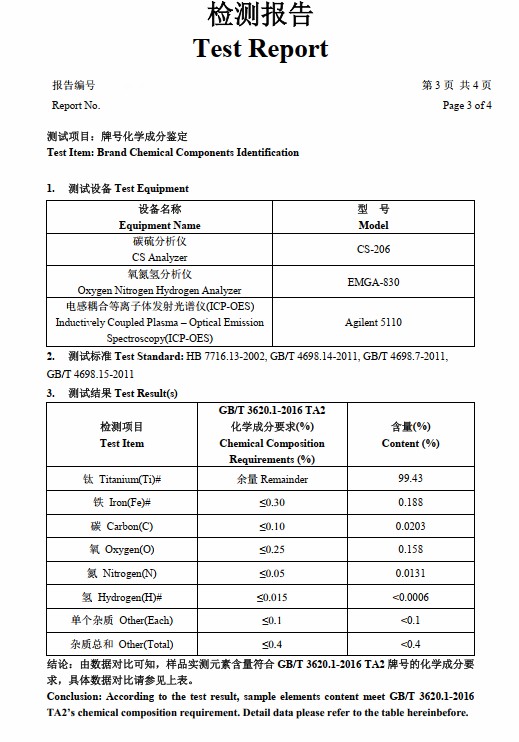

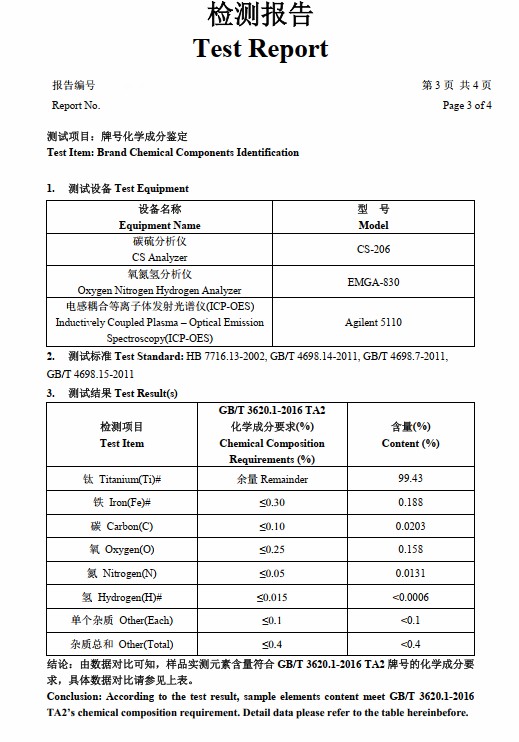

TA2 titanium alloy rod is the bushing's raw material. TA2 titanium alloy is a commercially pure titanium grade enowned for its excellent combination of properties, making it widely used in various industrial fields.

It primarily consists of titanium (typically over 99.5%) with trace amounts of impurities such as oxygen, nitrogen, carbon, hydrogen, and iron, which are strictly controlled to ensure its performance stability.

One of its key advantages is its outstanding corrosion resistance, especially in environments involving seawater, chloride solutions, and many organic acids, where it outperforms many traditional metals like steel or aluminum

Here is the material report:

The bushings are cut from the titanium alloy rod stock.

The bar is cut to the appropriate length using a bandsaw or circular saw, leaving extra material for subsequent machining. Then the bar is mounted in a lathe chuck, and centers are drilled at both ends to ensure precise alignment.

The outer diameter is reduced to near the final size using carbide cutting tools. Coolant is applied to manage heat generated by titanium's low thermal conductivity.

A pilot hole is drilled along the bar's centerline using a twist drill or gun drill, ensuring straightness and accuracy.

The hole is enlarged to the desired internal diameter using a boring bar. Precision is critical to meet tight tolerances.

Remove sharp edges from the OD and ID using a chamfering tool to facilitate assembly and prevent damage. Remove burrs from machined surfaces using abrasive tools or chemical processes to ensure a smooth finish.

Packing

Before packing, the caliper is used to verify OD, ID and length against design specifications. Check roughness using a profilometer to ensure it meets functional requirements. Remove machining residues using ultrasonic cleaning or solvents. We use EPE foam grooved boxes for individual placement to protect the surface.

By these steps, titanium alloy bar stock is transformed into a precision bushing ready for use in high-performance industrial applications.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

Afrikaans

Gaeilge

Eesti keel

latviešu

Беларуская мова

Български

Català

Lietuvių

Lëtzebuergesch

Македонски